Tensile strength σ psi compressive strength σ psi flexural strength σ psi modulus of elasticity e 10 6 psi porcelain.

Ceramic ultimate tensile strength.

In ductile materials yield strength is much lower than ultimate strength.

For a metal the compressive strength is near that of the tensile strength while for a ceramic the compressive strength may be 10 times the tensile strength.

The ultimate tensile strength is usually found by performing a tensile test and recording the engineering.

Ceramic steel industry.

1260 to 1760 product name.

Porcelain is a ceramic material made by heating selected and refined materials often including clay in the form of kaolinite to high temperatures.

Ultimate tensile strength decreased from 244 mpa in the as received condition to 107 mpa after exposure to 1000 c.

Cmc materials with a low matrix content down to zero have a high tensile strength close to the tensile strength of the fiber but low bending strength.

Ultimate tensile strength often shortened to tensile strength ultimate strength or f tu displaystyle f text tu within equations is the maximum stress that a material can withstand while being stretched or pulled before breaking.

Cmc materials with a low fiber content down to zero have a high bending strength close to the strength of the monolithic ceramic but no elongation beyond 0 05 under tensile load.

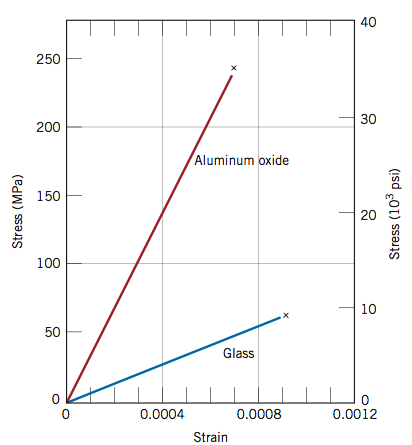

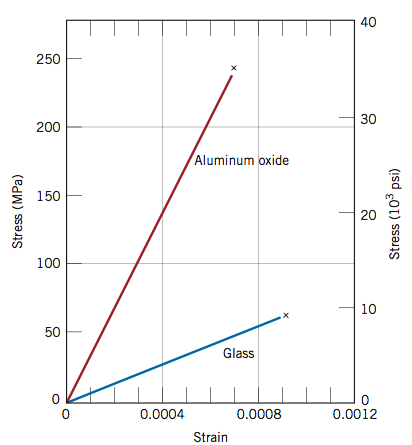

Alumina for example has a tensile strength of 20 000 psi 1138 mpa while the compressive strength is 350 000 psi 2400 mpa.

They provide high wear heat and corrosion resistance as well as high tensile strength volume resistivity dielectric strength and modulus of elasticity.

For ductile materials ultimate strength is roughly 1 5 times higher than yield strength.

Then based on the tdfs model and curtin theory a temperature dependent ultimate tensile strength tduts model for unidirectional ceramic fiber reinforced ceramic composites ucfrccs is established which considers the combined effects of the load carrying capacity of broken fibers and its evolution with temperature.

Ceramics tend to be weak in tension but strong in compression.

Ceramic materials offer a number of benefits in a variety of applications.

Ultimate tensile strength uts is considered as the failure criteria for brittle material.

Ceramic insulation blanket refractory ceramic fibres.