The operation and construction principle of vacuum ceramic filter resemble those of a conventional disc filter but the filter medium is replaced by a finely porous ceramic disc.

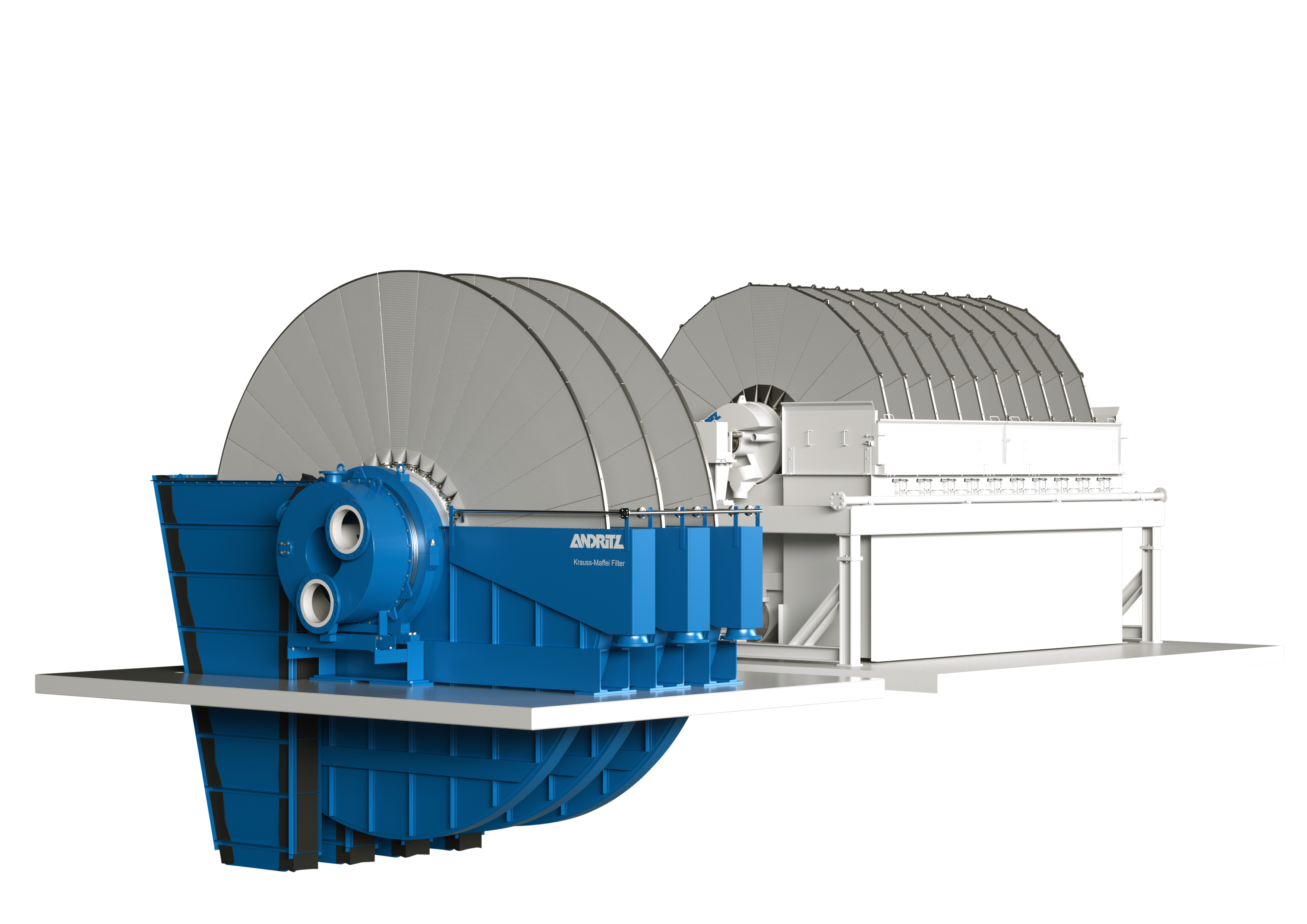

Ceramic vacuum disc filter.

The disc material is inert has a long operational life and is resistant to almost all chemicals.

Compared to conventional vacuum filters it consumes approximately 90 less energy.

The vacuum disk filter consists essentially of a slowly revolving drum the lower half of whose circumference is submerged in the pulp to be filtered.

This ensures that no air or particles are drawn into the filter medium to cause blockage.

Ceramic disc filters the ceramec filter is a unique rotary disc filter which uses a sintered alumina disc to dewater a slurry under low vacuum.

The dewatering occurs by drawing water from the slurry by capillary action.

The cx series ceramic disc vacuum cdv filter is a highly energy efficient rotary disc filter that uses ceramic membrane technology instead of cloth.

Flowrox cd filter operates continuously with high capacity and is cost efficient solution for many concentrator and tailings processes.