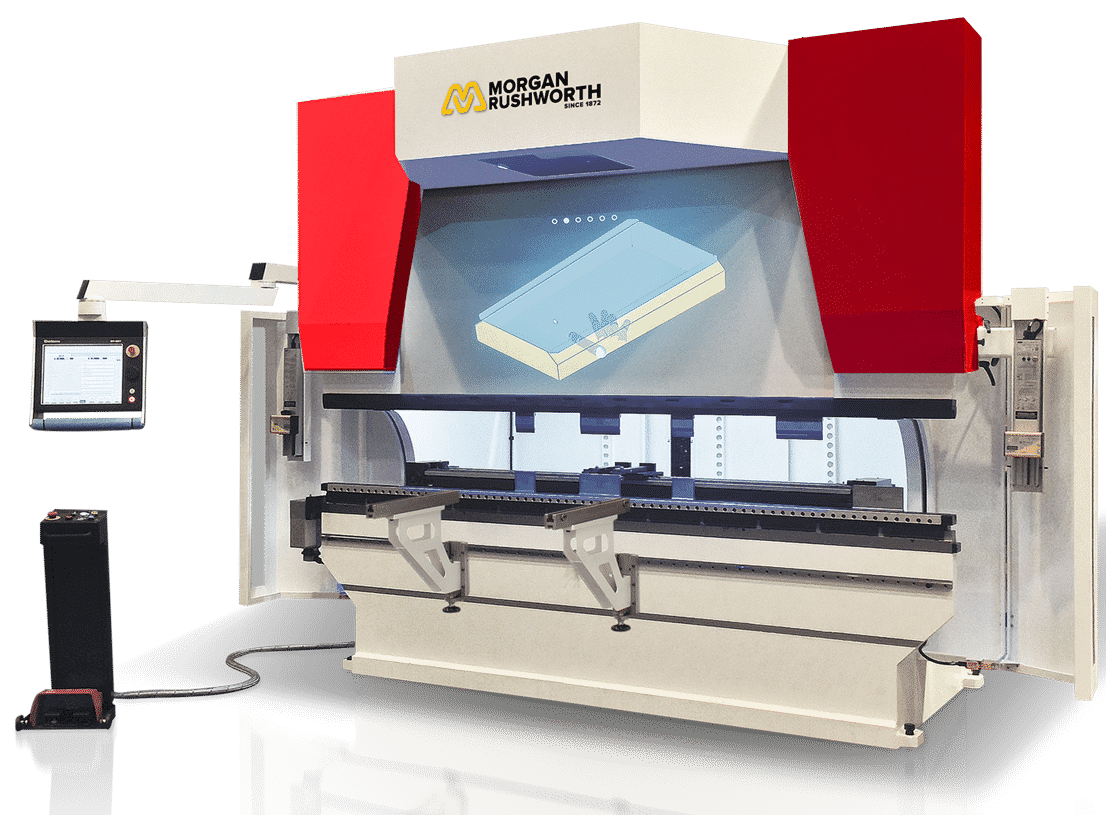

This means that the machine is controlled through software programming and plc controllers to provide the highest level of repeatability and all variables are controlled through the computer of the machine rather than manually such as pressure back gauge settings die.

Cnc art pressing sheet metal.

That is why this 63ton 1600mm cnc hydraulic press brake machine sheet metal cnc hydraulic bending machines has so big market in the world.

A press brake is a machine that is used to form bends in sheet metal parts.

Improvements in press drive technology machine control design tooling and cad cam programming software are increasing the throughput capability and the overall versatility of cnc turret punch press equipment in our shop.

Our cnc punches are state of the art.

In addition punch and die are used in combination to bend sheet metal from acute to obtuse angles with the highest of tolerances.

The ability to machine complex shapes undercuts and difficult angles in a single setup reduces tooling cost and labor time resulting in a better cost per part in addition to maintaining parts conformity.

Cnc press brake used to accurately form parts using a wide variety of material types thickness and radii.

Da52s da53t da58t da66t s530 s630 capabilities.

This press brake machine 63ton 1600mm can max bending 6mm thickness by 1 2m length and 5mm by 1600mm length.

A cnc turret punch press is a computer numerical controlled sheet metal fabrication machine that uses various sizes and shapes of tools to cut or punch out the profiles of sheet metal parts.

Cnc machining many industries today are turning to cnc machining as a means to speed manufacturing ability and increase repeatable accuracy.

Almacam bend is proposed with unfold alma s module for unfolding sheet metal parts from the model of the part designed in unfold or imported from an external cad software programming the press brakes can be easily managed with.

Cnc stands for computer numerical control.

So it is very convinient for all kinds customers for short sheet metal bending.

Mini cnc press brake da52s 3 1 axis we67k series cnc press brake the economical cnc solution.

With our huge tooling inventory they are very fast and versatile machines.

Kwandotechnic please like share and subscribe my ch.

The almacam bend software product can simulate the complete bending process and remotely program the leading brands of cnc press brakes in a highly automated way.

Press brake forming amada with 8 axis cnc control from simple right angle sheet metal bending to plate bump bending of cones hutchinson manufacturing s hmi equipment and experienced operators provide high quality repeatable parts that meet the demands of industry.